Pay less in medical claims costs and retain or attract excellent workers

Injury Prevention

It’s time to get on the right side of injuries with prevention

What is it?

Bardavon’s Injury Prevention Suite of products combines wearable safety technology and human intervention to prevent musculoskeletal disorders caused by workplace injuries.

Injuries Impact Everyone

Musculoskeletal disorders affect workers and cost employers’ money by leading to work stoppage, lost revenue, increased costs, and reduced morale.

Detect + Correct Risk

Wearable sensors detect risky movements to inform workers and safety pros of opportunities to correct how they approach daily job tasks.

Prevention Pays

A strain injury can cost upwards of $32,023 in direct costs. Preventing injuries not only protects employees, but a company’s bottom line.

How Bardavon’s Injury

Prevention Suite works

Everyone benefits when you prevent workplace injuries.

Wearable Sensors

Collect relevant data

Wearable sensors identify injury risks, alert workers of improper movements in real time, and collect data for applicable solutions.

Job Task Assessments

Set personal standards

Capture individual workers’ data as they perform job tasks, establishing a baseline to compare against future movement sessions’ data collection.

Movement Sessions

Correct risk

Identify risky movements based on captured information, altering ergonomics and behaviors to avoid injury.

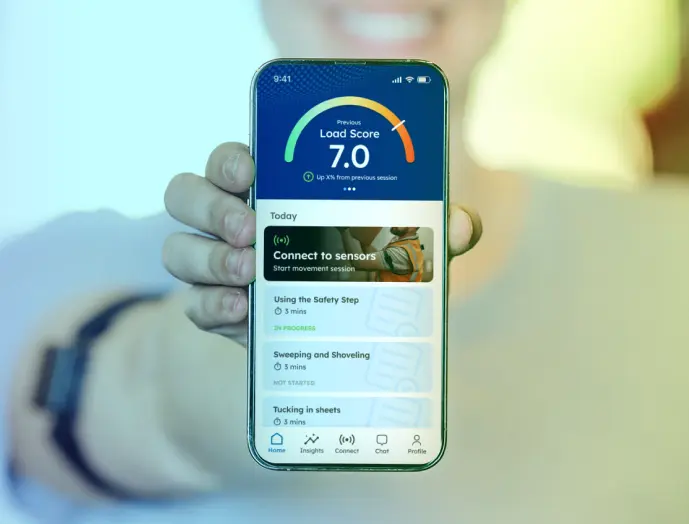

Prevention App

Prevent + protect

A simple app that displays how safely workers moved throughout their shift as well as exercises to improve performance.

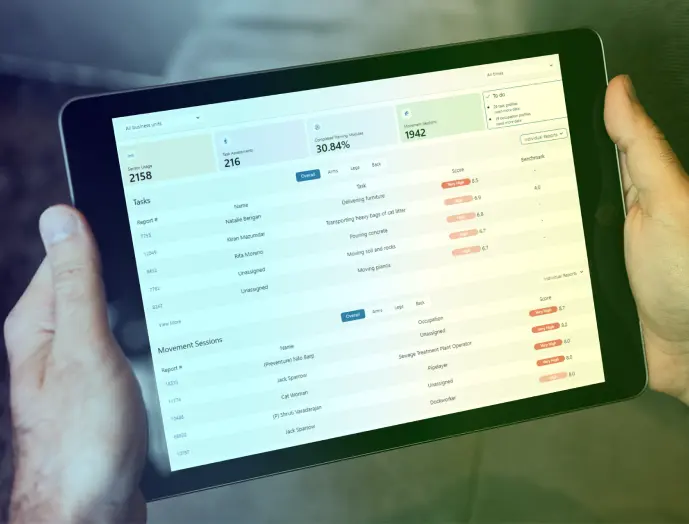

Dashboards

See risks your eyes miss

Display actionable data for safety professionals to understand which job tasks and individuals experience the most risk.

Wearable safety technology built for success.

Sensors capture worker movement without restrictions and are lightweight, durable, easy-to-wear technology.

Who benefits?

Avoid workplace injuries and maintain healthy movement on and off the clock.

Benefit from individualized movement data to aid in return-to-work care

Use actionable data to train workers and optimize safety culture

What’s your ROI?

Reduce claims and expenses with a product that can help avoid injuries.

Prevent injuries and reduce costs

An MSD strain injury costs on average $32,023. Indirect costs can multiply this by 2x.

Keep employees safe and healthy

Replacing one injured employee can cost six to nine months of that worker’s annual salary.

Reduce missed workdays

Increase productivity by reducing absences. The median days out for a shoulder injury is 28 days.

Attract top workers with a safety culture

There are 4.1 million more active job openings than unemployed workers in the increasingly competitive market.

Recover right with Bardavon

Workers’ compensation cases managed with care.

FAQ’s

You have questions + we have answers.

The purpose of the program is to reduce the musculoskeletal injury risk of the workers—not to look over their shoulders. Wearable sensors are designed to detect potentially risky movements that may put a strain on body parts.

The wearable sensors identify when a worker has exceeded the acceptable International Organization for Standardization threshold for a task. The worker is then notified immediately through their phone app. Risky movements and moments of strain can also be reviewed at the end of a shift. The worker owns and controls the phone app.

The wearable sensors do not track location or work pace. Since the wearable sensors only detect risky or straining movement, they can’t tell the difference between healthy movement and dormant activities like standing still or taking a break. As a part of product onboarding, workers are informed of what information the employer can and cannot access.

No, our wearable sensors are unobtrusive. They are lightweight and worn on the back collar of a shirt, jacket, or coat and around the bicep of the dominant arm. Wearable sensors can be covered by outerwear in cold environments and open to the elements in hot environments. They are designed to stay out of a worker’s way as they go about their job tasks.

It’s up to each safety professional, but we recommend workers wear the wearable sensors for a full week every three to four weeks.

Workers wear the sensors on a regular cadence established by their employer, for a full day’s shift for a week. It’s common for employers to have workers wear sensors for one week each month to see progress over time. Workers are able to review the data after each shift.

The wearable sensors are important in helping workers reduce injury risk and changing movement behavior, but incorporating a new feature into a routine is always a challenge. To help, we provide a worker engagement component to show that the purpose of the program is to support workers and reduce their risk of musculoskeletal injury. In this engagement training, workers will learn about the program from implementation to day-to-day use.

Since habits are hard to break, we know that workers are likely to fall back into their old habits after the first time wearing the sensors.

However, the wearable sensors are intended to inform workers about unsafe or straining movements that they may not realize they are doing. Increasing their awareness of movement health in their specific job tasks can help them maintain musculoskeletal health throughout their career.

Wearable sensors are worn every three to four weeks to follow up on progress. The wearable sensors and app are designed to be engaging. Wearing the sensors cues the worker to perform tasks correctly. At the end of each shift, the app provides a daily medal (Gold, Silver, Bronze) for their day’s performance. Ideally, workers will see improvements each time they wear the sensors as they learn to improve their movement techniques.

The product has the ability to monitor any task that involves movement–not just lifting. If you have jobs that have been determined to involve high-injury tasks, the product can be adapted to identify the risk. The program can monitor for overuse or repetitive movement that can increase injury risk overtime, even without heavy lifting. With the addition of the phone app and human coaching, your workers can learn preventative exercises to assist with reducing the injury risks related to those job tasks.

As important as safety is, many employers and employees fall into routines that don’t prioritize it.

Workers should know that safe movement health will help them stay healthy at work, but it also keeps them involved in the activities they enjoy at home for years to come.

Employers should know that safety is an area where employee health and budget goals align. Prevention is the most cost-effective way to address musculoskeletal disorders.

It depends, but it could be significant.

The exact ROI will depend on the types of injuries your workers might sustain, the number of injuries you see each year, and the amount of time workers might be out with an injury. Worker injuries are associated with direct and indirect costs that can add up.

Direct costs include higher workers’ compensation premiums, third-party administrator costs, and other medical costs. There are many more indirect costs, which can include production downtime, replacement hires, potential OSHA penalties, damage to equipment, and more.

A single injury could cost around $70,000 directly and $140,000 indirectly. Reducing just five injuries in a year could result in savings of more than a $1 million. That is many times more than the cost of our injury prevention product.

The wearable sensors measure workers’ movements throughout the day during their shift. They are specifically looking for movements that could lead to strain that increases the risk of injury or long-term wear and tear.

The wearable sensors are connected to a smartphone app and alert the worker when their movements surpass pre-established baselines that are based on International Organization for Standardization (ISO) thresholds and job task assessments.

Data is collected and can be reviewed at the end of a shift by workers and safety teams. This data includes when during the day and where on the body strain occurred.

The data is also useful in discovering which tasks are causing strain and which workers are experiencing the most strain. Bardavon will provide interventions, safety training courses, and exercises to improve employee movement health.

Connect today.

Complete the form below to connect with our team and learn how our Bardavon solutions can benefit your workplace.